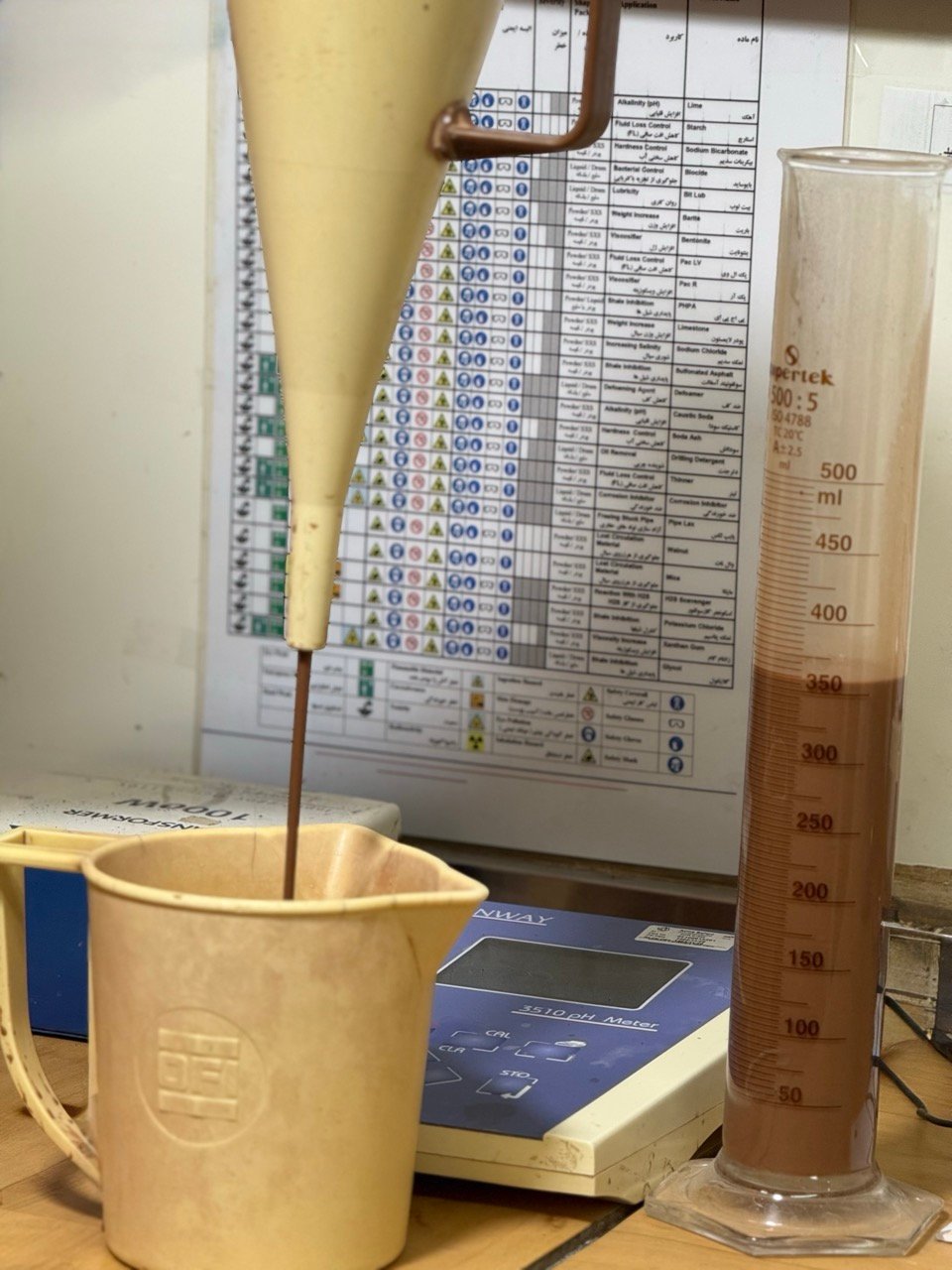

Drilling Fluid Additives

Our drilling fluid materials are engineered to deliver optimal wellbore stability, effective cuttings transport, and precise rheological control across diverse drilling environments. From water-based to oil-based systems, our portfolio includes viscosifiers, fluid loss control agents, shale inhibitors, and lubricants—all designed to enhance drilling efficiency, minimize formation damage, and ensure downhole compatibility under varying pressure and temperature conditions.

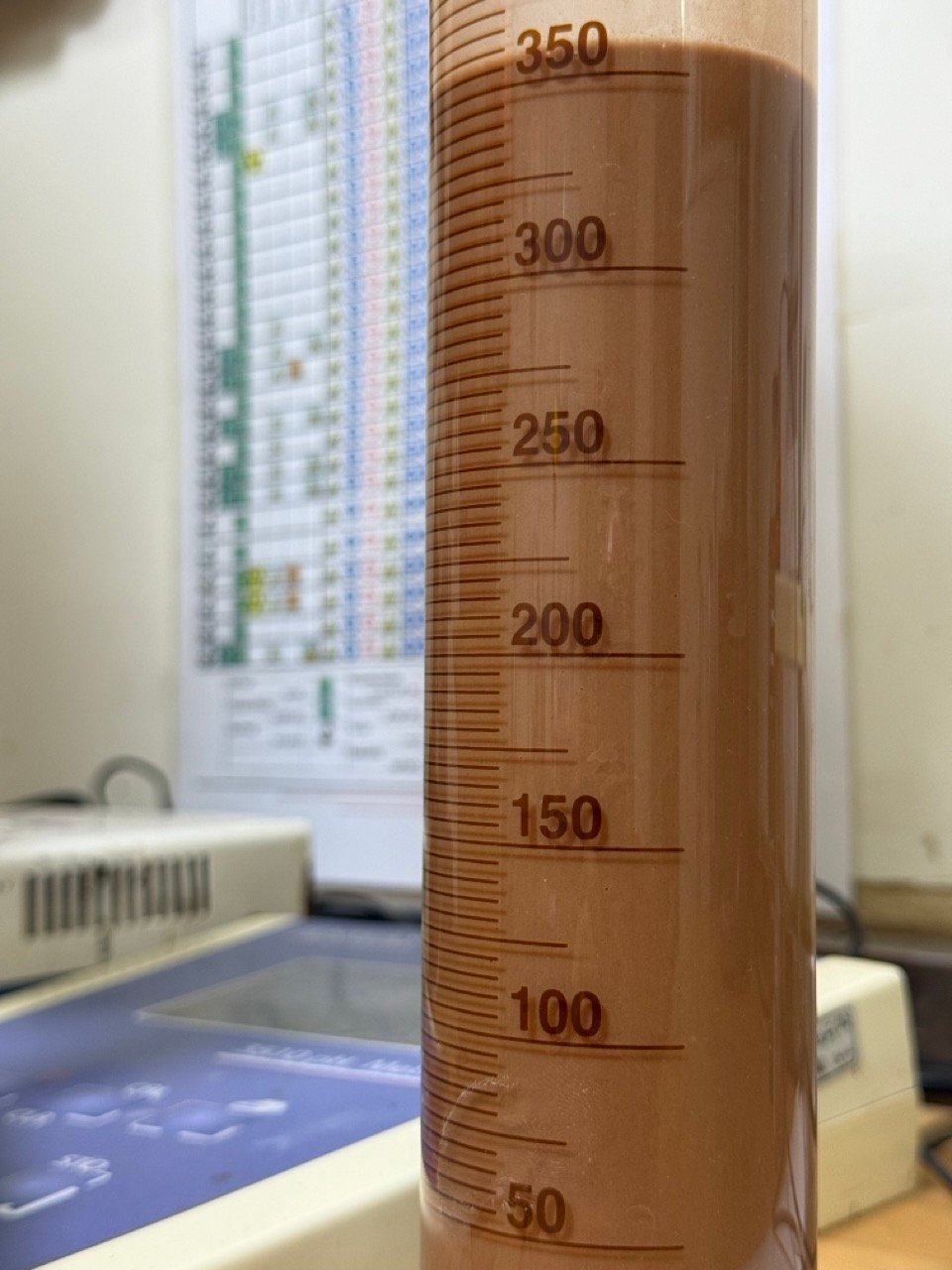

Bentonite

A clay-based additive used to increase viscosity and improve the carrying capacity of drilling mud. It also helps in forming a filter cake to prevent fluid loss.

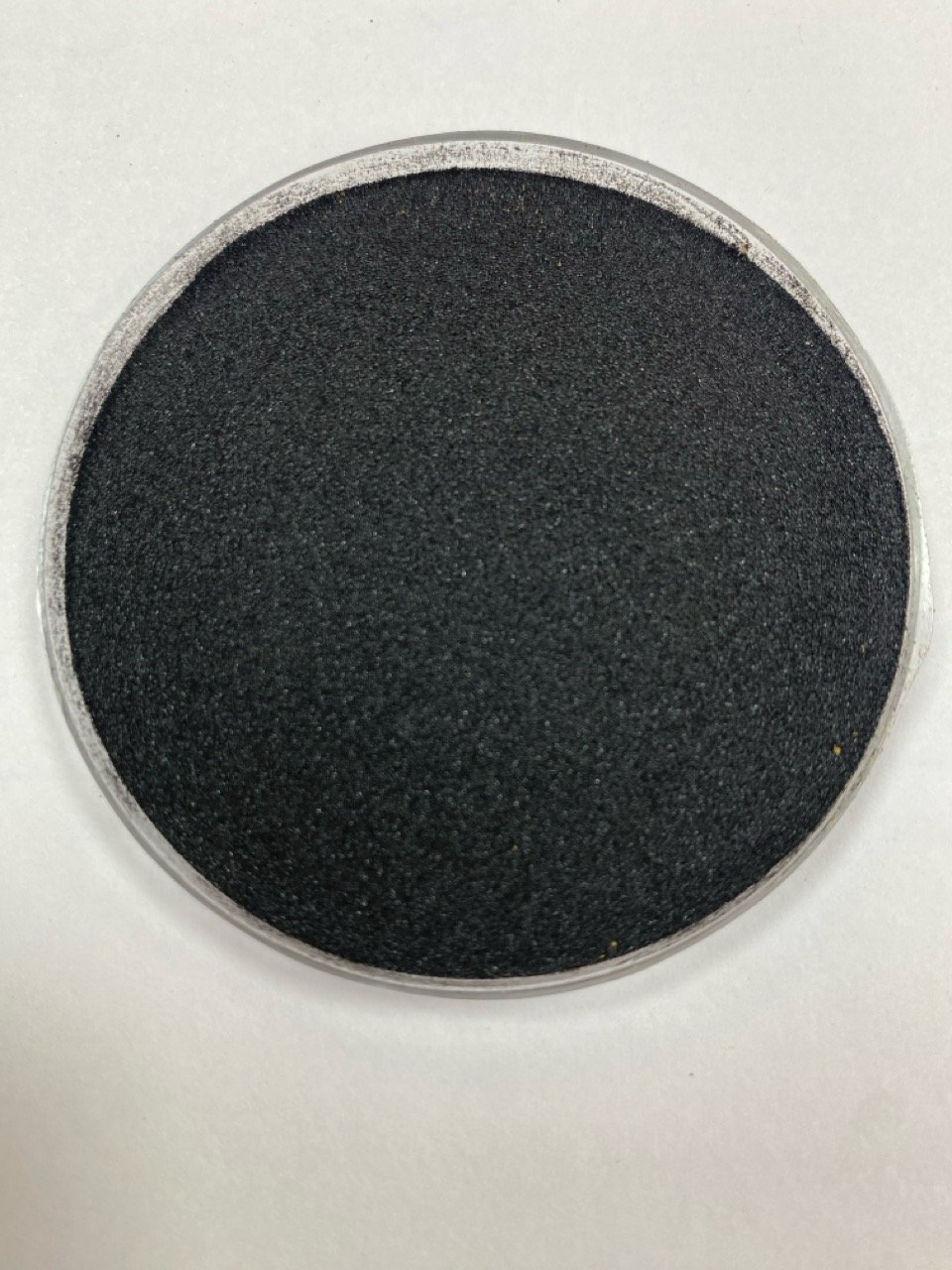

Barite (Barium Sulfate)

A weighting agent that increases the density of the drilling fluid to control formation pressure and prevent blowouts.

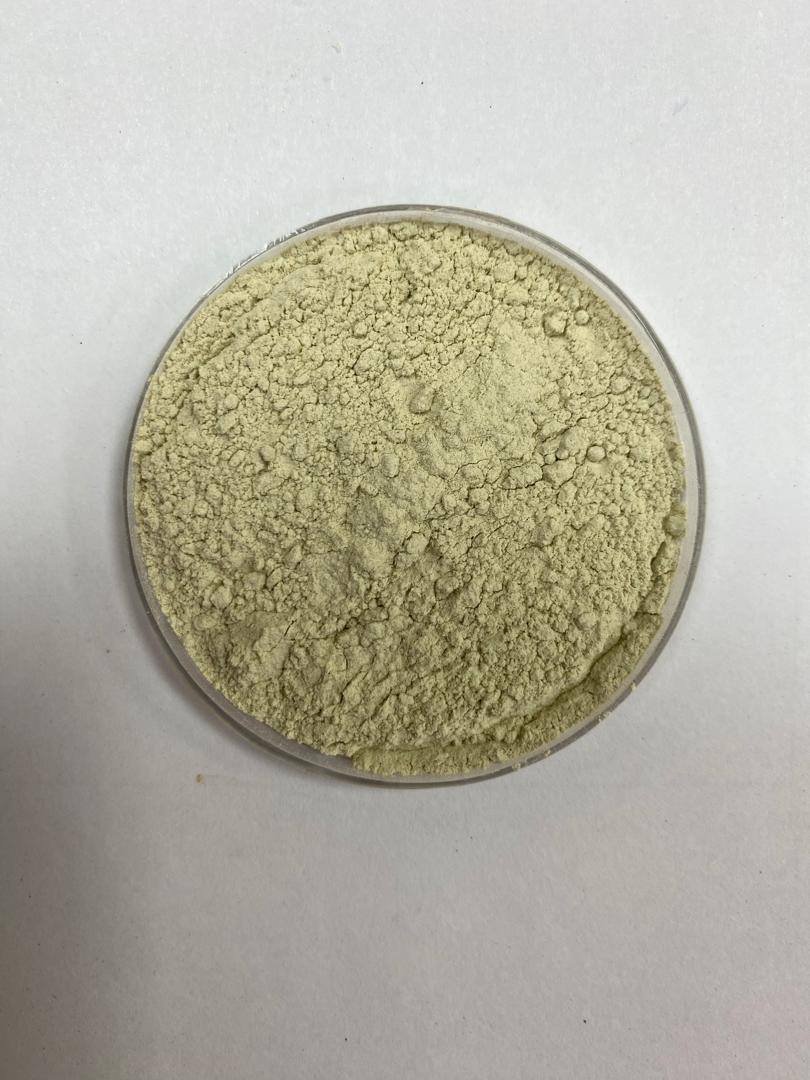

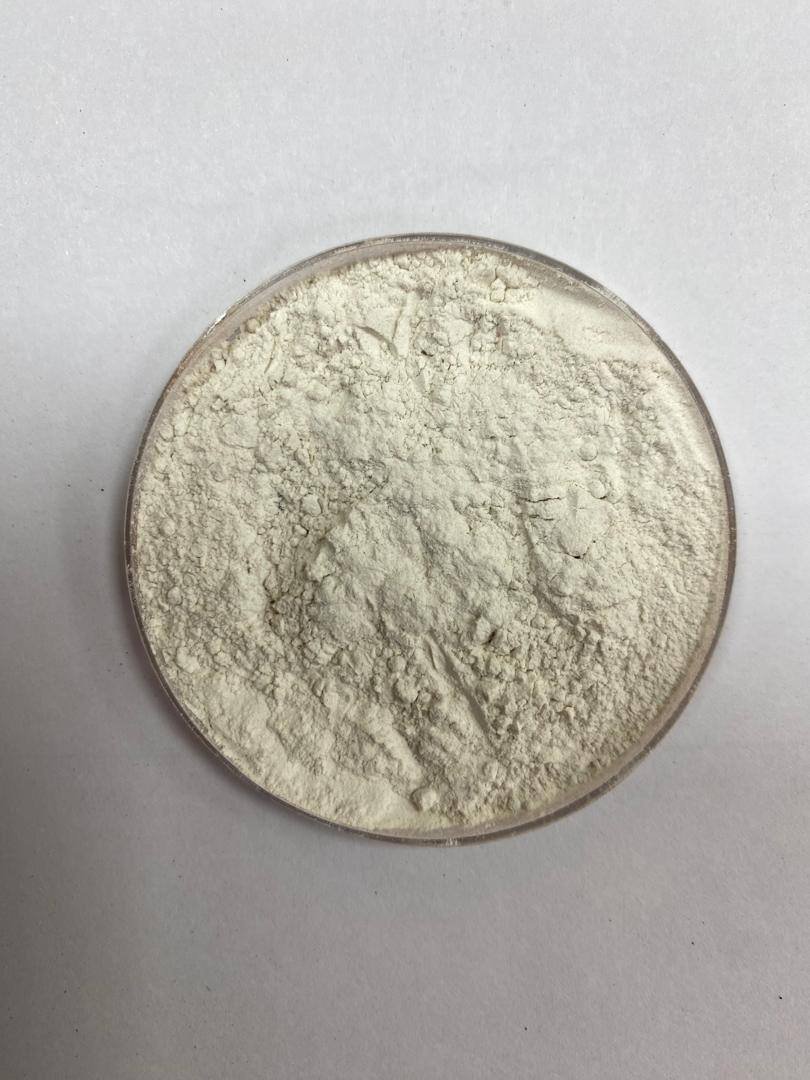

Polymers

Used to control rheology, increase viscosity, and reduce filtration loss. Examples include PAC (Polyanionic Cellulose) and CMC (Carboxymethyl Cellulose).

Shale Inhibitors

Prevent shale swelling and disintegration in water-sensitive formations. Common examples include KCl and amine-based inhibitors.

Biocides

Control microbial growth that can degrade polymers or produce hydrogen sulfide in the mud system.

Caustic Soda

Use in drilling fluids to raise pH, enhance clay dispersion, reduce Ca contamination and maintain the performance of polymers